BKR series roller brake tester is an up-to-date one to measure vehicles brakingperformance. During testing, the slip rate between wheel and roller is monitored todetermine the maximum brake force automatically. The testers driving motor would be shudown automatically either when testing finished or vehicle tested runing out of the tester inorder to protect tires very wel. Ceramic roller surface makes the friction factor more than 0.6 either being we/dry to avoidthe tire damage. All frames made with high-quality steel and galvanized or painting sprayed. BKR can test either 2WD or 4WD vehicles with additional sub-assembly.

BKR series roller brake tester is an up-to-date one to measure vehicles brakingperformance. During testing, the slip rate between wheel and roller is monitored todetermine the maximum brake force automatically. The testers driving motor would be shudown automatically either when testing finished or vehicle tested runing out of the tester inorder to protect tires very wel. Ceramic roller surface makes the friction factor more than 0.6 either being we/dry to avoidthe tire damage. All frames made with high-quality steel and galvanized or painting sprayed. BKR can test either 2WD or 4WD vehicles with additional sub-assembly. Brake force per wheel N Drag force per wheel N brake force of hand braken N Deceleration per axleor %or m/s2 Deceleration of whole vehicle %or m/s2 Imbalance per axle % Round out of wheel %Running on Windows Vehicle information registration Brake force curves Self diagnostic Self zeroing for each test Sensors mal-function indication Intelligence calibration aided Test data base Summary report and curve report output RS-232 and Ethemet ports English version software and other language availableWith Windows based software, all test procedureswill be carried out automatically. There is adatabase to let customer easy to trace back andsearch test results.

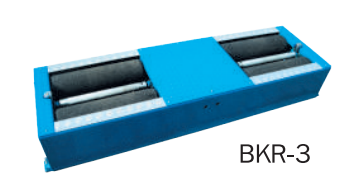

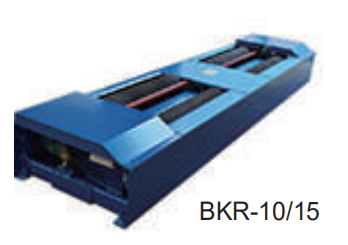

Brake force per wheel N Drag force per wheel N brake force of hand braken N Deceleration per axleor %or m/s2 Deceleration of whole vehicle %or m/s2 Imbalance per axle % Round out of wheel %Running on Windows Vehicle information registration Brake force curves Self diagnostic Self zeroing for each test Sensors mal-function indication Intelligence calibration aided Test data base Summary report and curve report output RS-232 and Ethemet ports English version software and other language availableWith Windows based software, all test procedureswill be carried out automatically. There is adatabase to let customer easy to trace back andsearch test results.| Items | BKR-3 | BKR-10(15) |

| Axle load allowed(kg) | 3000 | 10,000 (15,000) |

| Brake force range per wheel(N) | 2X6,000 | 2X30,000 (2X40,000) |

| Roller diameter(mm) | 200 | 245 |

| Roller lateral spacing(mm) | 380 | 445 |

| Testing speed(km/h) | 2.2 | 2.3 |

| Track distance Min(mm) | 900 | 950 |

| Track distance Max(mm) | 1800 | 2600 |

| Roller set dimension(mm) | 239X725X375 | 4200X980X520 |

| Accuracy | ±%3F.S. | ±%3F.S. |

| Drive motor(kw) | 2X2.2 | 2X11 (2X15) |

| Operation temperature(°c) | 5-40 | |

| Roller surface | Cramic coating | |

| Weight(kg) | 950 | 1800 (1850) |

| U3 console body | Corrosion free surface by powder Spray, moving foots |

| Computer system | Industrial PC, Intel Core 2, 2G Memory, 1T HardDisk, 10/100M Ethernet Port, 19’LCD, Laster jet A4 |

| Net-working | TCP/IP |

| Compress air supply | 0.6~0.9 MPa |

| Power supply | 220VAC 50Hz kW |

| Operation tempe rature | 5~40℃ |

| Operation humidity | ≤90% |

| Dimension | 900×600×1100mm |

| *Note: Other specification of power supply is available on request. | |